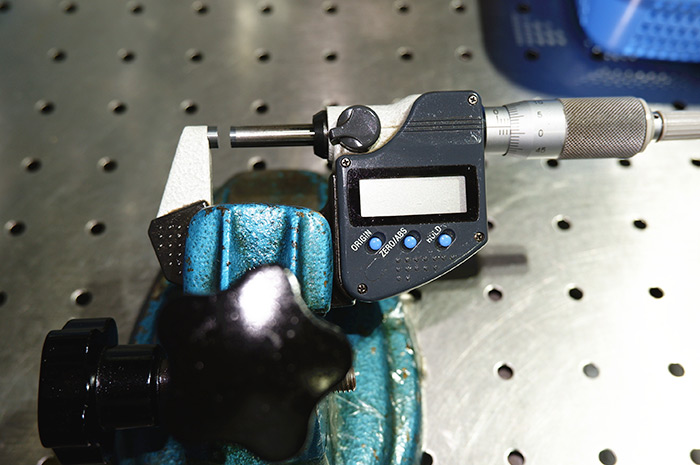

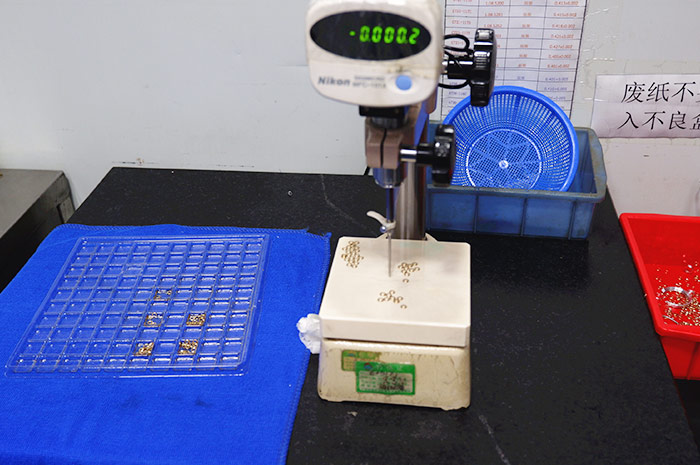

The test instrument includes CMM, Projector, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter etc.. And we hired the well-trained people to do the quality control job. In order to provide high quality machined parts every time, we strictly follow quality checking process as below:

· RAW MATERIAL INSPECTION

Our QC team will inspect all raw materials once they are purchased. They will check the size, hardness, and composition with external help.

· IN-PROCESS QUALITY CHECK

In the manufacturing stage, no matter which process is finished, parts and components would be measured to make sure everything is correct.

· FINAL INSPECTION

When a part is completely finished, the full inspection will be processed. Size of every position will be checked. QC will check if it fits other parts in case it needs to.

· OUTGOING QUALITY CONTROL

Each shipment will be checked carefully by our QC before shipping. A detailed packing list will be placed into boxes. QC will check if all parts needed have been placed in the box, if shipping address and contact details are correct, etc.

Quality is everything, we completely understand the importance of quality for each precision machining processes. Therefore, we have applied strict quality control system on all machining processes. We can't tolerate any tiny fault at our products. We equipped us with adequate measuring and testing equipment which is needed in the quality checking process.

|  |

| Micrometer | Precision Altimeter |

|  |

| Precision Projector | Quadric Detection Instrument |

Previous: Equipment

Next: OEM Products Display